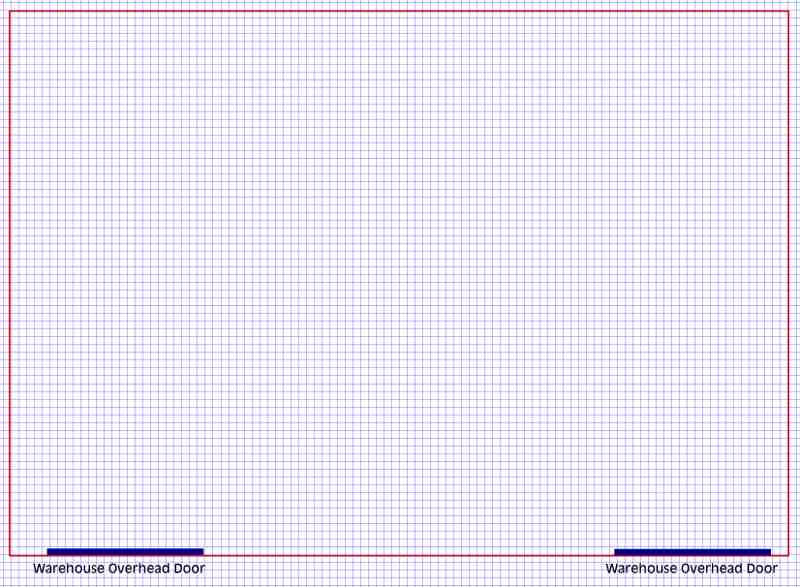

- WAREHOUSE BLUEPRINT BACKGROUND INSTALL

- WAREHOUSE BLUEPRINT BACKGROUND FULL

- WAREHOUSE BLUEPRINT BACKGROUND SOFTWARE

- WAREHOUSE BLUEPRINT BACKGROUND SERIES

WAREHOUSE BLUEPRINT BACKGROUND SOFTWARE

WAREHOUSE BLUEPRINT BACKGROUND FULL

“Without it, you just start filling up space and before you know it, it’s full – and underutilized. “There’s a need for companies to enter a warehouse with a strategy to accommodate growth,” says Hutchins. “The lesson from this case”, says Hutchins, “is that the key to a successful warehouse is planning ahead.” They went from 20 pallets on the ground to an additional 50 pallets on the rack, at least doubling their storage.” Next Steps The Real Solution is to Call Us First! “Plus, they were previously stacking pallets 2 high on the ground level. They’ve been very happy with it since we’ve installed it,” says Hutchins. “Since the safety and efficiency of this plan was proven, they’ve added the rack backing to safeguard other areas in their facility. And the entire layout was installed in just under 2 days by our certified and trained installation team. Thousands of new, high-quality pictures added every day.

Thanks to the affordable wire backing systems from Folding Guard and Interlake Mecalux’s ability to ship quickly and affordably from Dallas, the new rack system was available about 2 weeks after ordering. Find Paint Blueprint stock images in HD and millions of other royalty-free stock photos, illustrations and vectors in the Shutterstock collection.

WAREHOUSE BLUEPRINT BACKGROUND INSTALL

“The rack backing fell under that category, so they were on board immediately.” Result: Double Down on Storage and Safety 2 Weeks Ship and 2 Day Install “They’re implementing a new safety strategy at this company and part of that is forklift safety,” says Hutchins.

This provides a solid protective barrier stopping products from being pushed off the back – keeping workers safe.

WAREHOUSE BLUEPRINT BACKGROUND SERIES

Rack back is made up of a series of strong, steel wire mesh panels which are bolted tight to the back of a pallet rack bay.

Next, to protect the workers traveling down this newly created pathway, “rack backing” or “rack backs” were installed along the backside to prevent product from falling off the rack. Rack back provides a solid barrier to keep workers safe.

0 kommentar(er)

0 kommentar(er)